Source: https://www.recyc-quebec.gouv.qc.ca/citoyens/mieux-consommer

We often hear that Quebecers are recycling champions. The 4Rs principle of sustainable development: Reduce, Reuse, Recycle and Recover… But today I would like to talk about the importance of the waste management hierarchy. Besides, I believe there is yet another R (Rethink) that must be added to the known 4Rs of waste management. It is about reviewing and rethinking our needs. It must become the very first step of resolving waste management problems. I’ll show you that we can transform costs into savings by moving away from the waste treatment approach towards waste prevention, or in other words by focusing on Rethink, Reduce and Reuse!

Question & Rethink

One SME leader working in the service sector told me that the challenge of “raw and waste materials management” is not relevant in the case of his company because there is already a recycling bin in every office. However, after we talked for a few minutes, we realized that all employees were scheduled to get a new laptop every 2 years.

Me: Why do you upgrade all laptops every 2 years? Is there a real need for it?

Manager: Silence… Well, it’s in the agreement we signed with our provider… But we do recycle the old ones!

Me: Do you think that you could both generate savings for your company and reduce the negative impact on the environment if you were to have your laptops upgraded based on the actual needs of your employees instead of a predetermined fixed replacement schedule?

You can imagine the rest of the conversation. This process of questioning your current business habits and rethinking your established processes can be done for all input (raw) materials. While responsible waste management is a good thing, it’s still waste treatment. Yet true cost savings are in prevention, which means focusing on and dealing with the input materials.

Does it sound familiar? What are the potential savings for your company if you review and rethink your consumption based on YOUR ACTUAL NEEDS?

The 5Rs – Recycling Hierarchy

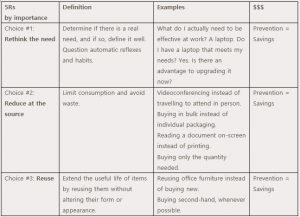

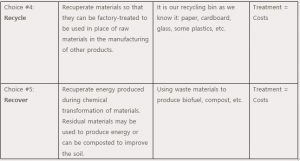

So what is the waste management hierarchy all about? Here is a table that lists, in order of preference, the actions that are both profitable for your business and good for our planet.

Based on: “Principes et mesures d’approvisionnement responsable: contribuer au développement durable par ses décisions d’achat” by STM (Principles and Methods of Responsible Procurement: Contribute to Sustainable Development through Purchasing Decisions) https://www.stm.info/sites/default/files/pdf/fr/appro_resp.pdf

All these options are better than landfills and disposal sites, but they are listed in order of importance and profitability. Indeed, goods that don’t have to be purchased because the need was rethought, their consumption was reduced at the source or they were reused (which imply savings), also do not have to be recycled (thus avoiding costs that result in savings).

Be a Responsible Business

On the website of the Ministry of Sustainable Development, Environment and the Fight against Climate Change we learn that:

”On average, Quebecers generate 25 tons of non-hazardous residual materials per minute. Despite the educational efforts and the means offered to the public, municipalities, as well as industrial, commercial and institutional establishments in order to enable them to reduce their production of goods and reclaim their waste, still too many consumer products are ending up in landfills and disposal sites…. In fact, some 13 million tons of residual materials produced in Quebec annually hold undeniable potential to be used both in the manufacturing of goods and for energy production.”

Reference: http://www.mddelcc.gouv.qc.ca/matieres/inter.htm

I absolutely agree with the idea of avoiding the landfill end of life of goods, but I would rather prefer to see the focus shifted towards the importance of the steps that precede recycling. Why not rename RECYC-QUÉBEC… to be more coherent… 5R-QUÉBEC? Seriously, whether you’re a manufacturing or service company, it is possible to focus on prevention by reviewing all input materials and goods to be able to offer your products/services, to organize events or to meet the needs of the employees: electronics, office furniture, cafeteria, bottled water, supplies, etc.

A simple way to get the attention of your colleagues is to give them the annual stats on the volumes and costs related to the management of residual materials (businesses are charged for recycling and trash containers and related services (quantity and price)). As we all know, the first step towards change is awareness.

Informed Decisions, Not Imposed Changes

Consumers and businesses alike have all the right to manage their own rate of consumption. It is up to us to identify our needs and to make educated choices in line with our values, our resources and our restrictions. What’s the link with the 5Rs of waste management? Enough with the culture of disposable goods and planned obsolescence! The very definition of sustainable development (“development that meets the needs of the present without compromising the ability of future generations to meet their own needs”) focuses on the “needs”. But what does a NEED mean? Having the latest iPhone model… is it a need or a want?

The problem starts when the “need” is imposed on us by planned obsolescence. Examples? According to the article on Planned Obsolescence published by GaïaPresse:

According to the same source:

Source: http://www.gaiapresse.ca/2018/01/obsolescence-programmee-grand-gachis/

So, how much do you think your company could save by simply applying the principles of this 5Rs hierarchy? I challenge you to make your own calculations…

Marie-Josée Roy

Sustainable Development & Strategic Management Expert

Totem Performance organisationnelle